Qinlang focuses on providing high-quality products and considerate services, and is committed to meeting every expectation of our customers.

The DKT-133 Cooling Ventilation Double Inlet Air Conditioning Fan is d...

See DetailsIn modern HVAC systems and industrial ventilation setups, choosing the right type of fan can have a significant impact on efficiency, energy use, and overall performance. Among the various fan designs available, the backward curved impeller fan stands out for specific applications. Whether you're dealing with high static pressure systems or seeking a low-maintenance solution, the backward curved fan offers several advantages over other fan types. But when exactly should you choose one?

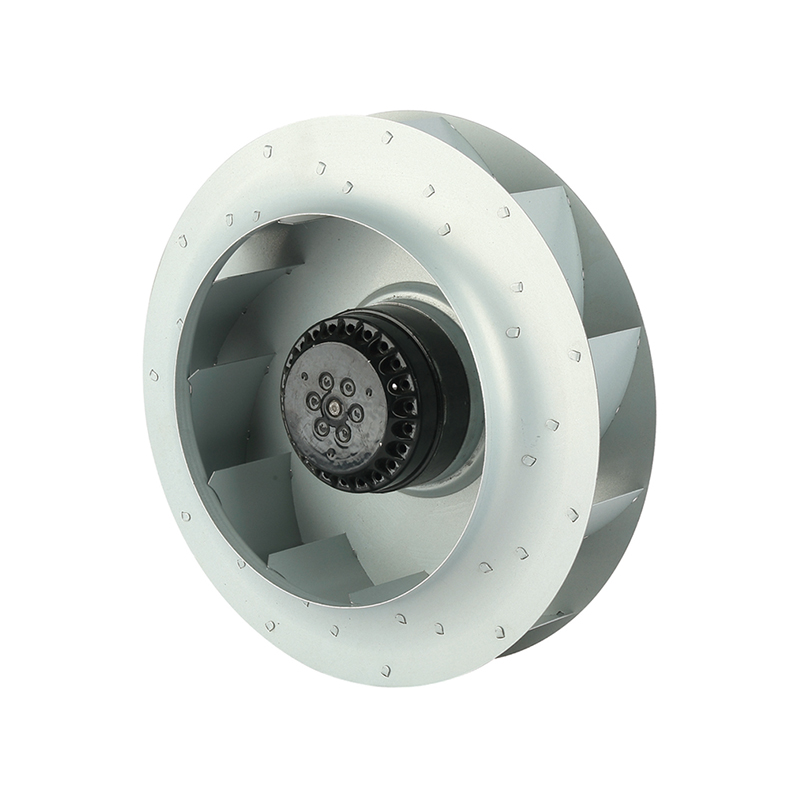

First and foremost, the backward curved impeller fan is ideal when your system requires high static pressure. Unlike forward-curved fans or axial fans, this type of fan is designed to handle resistance efficiently. The backward curved fan blades are shaped in a way that reduces turbulence while maintaining strong airflow against pressure. This makes it an outstanding choice for applications such as clean rooms, fume extraction, and duct systems with complex routing.

Another key reason to opt for a backward curved fan is its energy efficiency. Due to the aerodynamic design of the backward curved fan blades, the fan can move air using less power, especially at higher pressures. The impeller blades curve away from the direction of rotation, which reduces the risk of stalling and ensures smooth operation. This translates to lower operating costs and a smaller environmental footprint over time, which is particularly appealing for facilities focused on sustainability.

In environments where reliability and low maintenance are critical, the backward curved impeller fan shines again. Its robust design has fewer moving parts compared to some other fan types, and the backward curved fan blades tend to accumulate less dust and debris. This results in less frequent cleaning and reduced wear and tear, which lowers maintenance demands. Whether in industrial applications or large-scale HVAC systems, the backward curved fan offers long-durability and consistency.

Sound levels are also an important consideration in many applications, from commercial buildings to hospitals and schools. The design of the backward curved fan blades helps minimize noise by ensuring smoother airflow and less turbulence. For sound-sensitive environments, the backward curved impeller fan can be paired with acoustic insulation or silencers to create an even quieter operation.

Another factor that makes the backward curved fan preferable in specific use cases is its ability to maintain performance across a wide range of speeds. Some ventilation systems operate at variable speeds depending on occupancy or environmental conditions. The backward curved impeller fan performs well even when fan speeds fluctuate, without a significant drop in efficiency or airflow. This adaptability is especially beneficial in dynamic environments like laboratories or commercial kitchens.

Moreover, the backward curved fan blades offer outstanding safety. Since these fans are non-overloading, their power consumption peaks at a certain point and then drops if the system becomes blocked. This protects the motor from overheating or burning out, adding another layer of reliability to your system.

When high static pressure, energy efficiency, reliability, low noise, and safety are top priorities, choosing a backward curved impeller fan is the logical move. Its unique design and engineering provide consistent performance where other fan types may struggle. Whether you're an engineer, facility manager, or contractor, understanding the benefits of backward curved fan blades and the situations that call for a backward curved fan will help you make smarter, more efficient decisions for your ventilation needs.