Qinlang focuses on providing high-quality products and considerate services, and is committed to meeting every expectation of our customers.

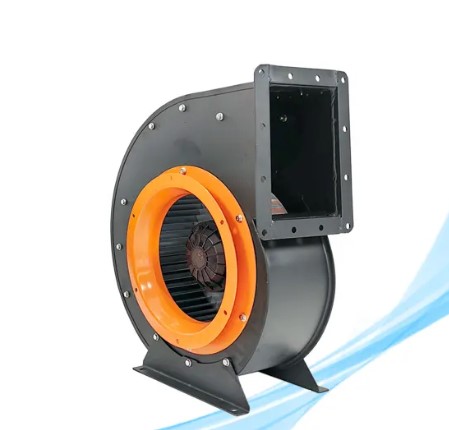

The DKT-133 Cooling Ventilation Double Inlet Air Conditioning Fan is d...

See Details

A common scenario in the industry is that upgrading to high-efficiency motors does not always bring the expected improvement in overall fan efficiency. Misalignment between components often leads to operational abnormalities, such as excessive vibration, subpar energy efficiency, and unstable operation. Moreover, the matching and calibration process between motors and fans is usually cumbersome and time-consuming, directly affecting production progress and disrupting original production schedules.

The root cause of this problem lies in a common cognitive misunderstanding: overemphasizing the performance of individual components while ignoring the coordination logic of the entire system. The core issue resides in the imbalanced collaborative matching between impeller angle, volute flow channel, and motor speed—any mismatch in these aspects will affect the overall performance. Technically, many manufacturers lack precise testing tools and sufficient accumulated experience in calibration. Additionally, there is often a disconnect between design and production stages; during the early design phase, the feasibility of matching in subsequent processing is not fully considered, laying the groundwork for future problems.

To address this issue, HVAC Centrifugal Fan Manufacturer should first establish a "component and complete machine collaborative design" system to identify and avoid potential matching problems in the early design phase. Secondly, the calibration process must be standardized—clarifying steps and defining reasonable parameter ranges to reduce differences in manual operations. Introducing auxiliary testing tools can improve calibration accuracy. Meanwhile, strengthening technical training for production personnel and compiling practical experience into a shared database will help enhance the overall calibration level.

Traditional noise reduction methods have reached their limit, making it difficult to meet the stringent requirements of high-end scenarios. There is also a tricky contradiction here: some noise reduction measures may inadvertently increase energy consumption. Furthermore, the superposition of aerodynamic noise and mechanical transmission noise makes noise reduction more challenging. What's more, the effectiveness of noise reduction is unstable—it can be affected by different installation conditions and operating environments.

The main issue is insufficient in-depth understanding of the technology. Many manufacturers do not fully grasp how aerodynamic noise is generated or how to control it effectively. In addition, structural design flaws, such as unreasonable blade curvature and poorly designed volute flow guiding structures, can cause turbulent airflow, leading to increased noise. Material selection and processing technology also play a role; materials with poor sound insulation and shock absorption properties, coupled with unobstructed vibration transmission, make it difficult to control noise. Moreover, inadequate process control during production can result in deviations in processing accuracy, rendering the originally designed noise reduction structures ineffective.

In production, pursuing better noise reduction performance requires more investment in R&D and testing, and the production process becomes more complex. In the market, failure to meet noise requirements means being excluded from high-end scenarios, and it is difficult to reflect product differentiation. For customers, excessive noise impairs the user experience, leading to more after-sales feedback and complaints.

Addressing noise reduction issues requires targeted measures. For aerodynamic noise, optimizing blade structure design and improving the airflow direction inside the volute can reduce turbulent airflow and thus lower noise. For mechanical transmission noise, methods such as optimizing material selection, adding shock absorption structures, and blocking vibration transmission paths are effective. It is also necessary to establish a "testing-optimization" closed loop, monitoring noise reduction effects throughout the production process and adjusting plans based on actual conditions to ensure stable performance. In addition, improving processing accuracy is crucial; otherwise, even well-designed noise reduction structures will not achieve the expected results.

Market demand for customized HVAC centrifugal fans is growing, with frequent requests for special sizes, adaptations to specific working conditions, and customized functions. However, traditional mass production lines have poor flexibility—switching to different specifications is both costly and time-consuming. The conflict between customized orders and standardized production is obvious, leading to disorganized material management, disrupted production plans, delayed delivery of customized orders, difficult cost control, and ultimately affecting profitability.

The core reason is the increasing diversification of market demand—different industries and scenarios have different requirements for fans, all requiring personalized solutions. However, the current production model is too backward, focusing on standardized mass production and unable to quickly adapt to changes in customer needs. Moreover, the collaboration between design and production is inadequate; customized designs lack support from standardized modules and are incompatible with existing production processes. In addition, the supply chain's response to customized material needs is too slow to keep up with the production rhythm.

To resolve this conflict, comprehensive adjustments to production and operational models are needed. Promoting modular design is a good approach—breaking the fan into several core modules and combining modules according to customized needs can simplify production and reduce line change costs. Building flexible production lines equipped with quickly adjustable equipment and processes can adapt to different order requirements rapidly. It is also necessary to establish a dedicated production process for customized orders, optimizing links such as order review, design, material procurement, and production scheduling to make the process smoother. Strengthening cooperation with the supply chain, building a flexible supply chain, and improving the response speed of customized materials can timely support production. Finally, establishing a digital production management platform allows real-time visibility and precise control of orders, production, and materials.

Manufacturers have always faced a dilemma: how to balance raw material selection and product durability. Different operating conditions have different requirements for fans, such as temperature resistance, corrosion resistance, and wear resistance, which often conflict with the goal of cost control. Nowadays, there is a trend to use lightweight materials instead of traditional ones, but how to ensure structural strength and long-term durability while reducing weight is another challenge. In addition, unstable raw material performance will affect product quality consistency and long-term operational reliability. The application of new materials is also not smooth—immature technology, mismatched processing processes, and high costs are all obstacles.

Market demand is a key factor—different scenarios have significantly different requirements for fan durability. Different materials vary in performance, cost, and processing difficulty, requiring careful consideration during selection. The compatibility between materials and processing processes directly affects product durability and production efficiency. Volatile raw material prices and fierce market competition lead to great cost pressure, making balance more difficult. Finally, manufacturers lack sufficient technical reserves and understanding of new materials, which also affects the application of advanced solutions.

To solve this balance problem, a systematic raw material selection and process optimization plan is needed. First, establish a precise selection system, formulate clear selection standards based on operating condition requirements and cost budgets, and provide a basis for decision-making. Optimizing material combination strategies is also important—using high-performance materials for core components to ensure quality and cost-effective alternative materials for non-core components can both guarantee performance and control costs. Cooperating with material suppliers to promote the R&D and application of new materials can solve technical and process problems. It is also necessary to improve processing technology to adapt to the processing needs of new materials and ensure product structural strength and durability. Finally, strengthen the quality control of raw materials, strictly screen suppliers, and conduct good incoming inspections to ensure stable performance and consistent quality of raw materials.

Resolving these challenges in production and processing requires the cooperation and support of technology, talent, management, and the supply chain. Technically, establish a collaborative mechanism between design, production, and R&D departments to ensure smooth knowledge sharing and rapid problem-solving. Increase R&D investment to focus on overcoming core technical challenges such as matching, noise reduction, and material selection. Compile practical technical experience into a database for easy reuse to continuously improve and enhance.

Talent support is also indispensable. Strengthen technical training for production personnel, such as improving skills in core links like calibration, noise reduction, customized production, and material processing. Establish incentive mechanisms to encourage innovation and process optimization. Introduce professional talents to address technical shortcomings.

In terms of management, promote digital transformation to achieve visual and refined control of the entire production process. Improve the quality management system to conduct full-process supervision from raw material entry to finished product delivery. Optimize production planning and scheduling to improve the response speed to customized needs.

In the supply chain, deepen cooperation with core suppliers to ensure the quality and stable supply of raw materials. Develop a diversified supply chain to reduce reliance on a single supplier and lower risks. Improve the response speed of the supply chain to ensure timely delivery of customized materials to keep up with the production rhythm.