The AC-400 High Pressure Forward Bending Backward Curved Centrifugal Fan is a high-performance air m...

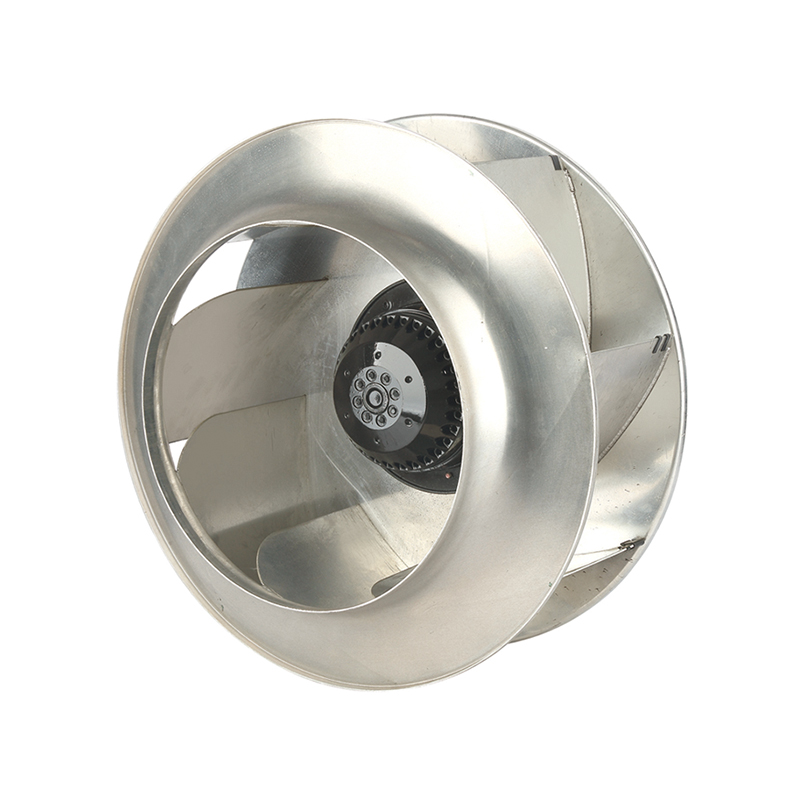

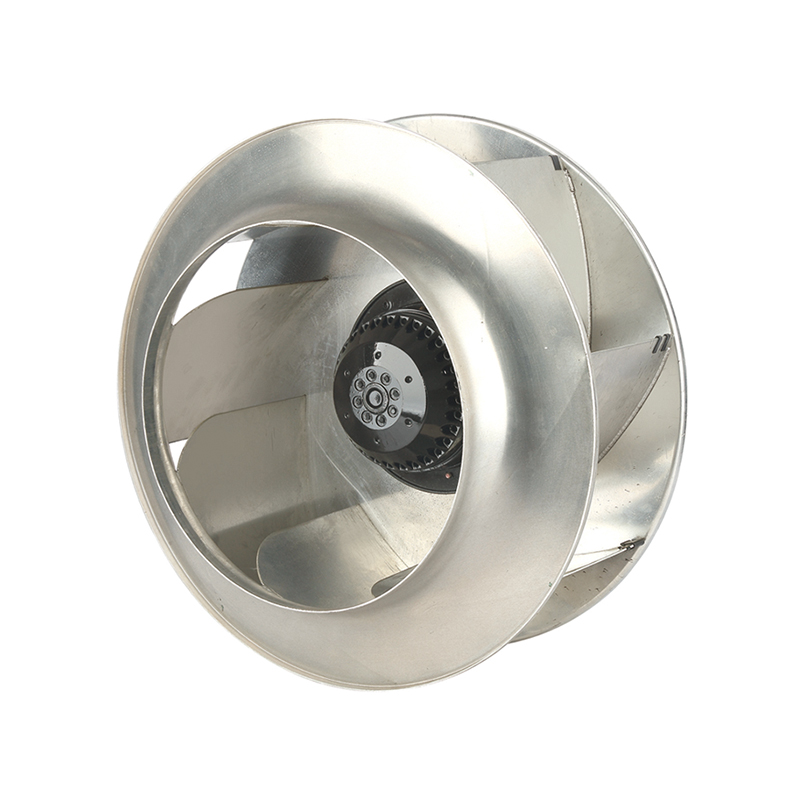

HVAC Centrifugal Fan

-

-

AC-450 Cool Down Backward Curved Centrifugal Fan

AC-450 Cool Down Backward Curved Centrifugal FanThe AC-450 Cool Down Backward Curved Centrifugal Fan is designed to deliver efficient and reliable a...

-

AC-500 Air Treatment Backward Curved Centrifugal Fan

AC-500 Air Treatment Backward Curved Centrifugal FanThe AC-500 Air Treatment Backward Curved Centrifugal Fan is a high-performance ventilation solution ...

-

AC-560 Round Housing Backward Curved Centrifugal Fan

AC-560 Round Housing Backward Curved Centrifugal FanThe AC-560 Round Housing Backward Curved Centrifugal Fan is an advanced air movement solution design...

-

AC-630 Performance, Dc Backward Curved Centrifugal Fan

AC-630 Performance, Dc Backward Curved Centrifugal FanThe AC-630 Performance DC Backward Curved Centrifugal Fan is an advanced air-moving solution designe...

-

LX-501B Square Housing Two-Speed Backward Curved Centrifugal Fan

LX-501B Square Housing Two-Speed Backward Curved Centrifugal FanThe LX-501B Square Housing Two-Speed Backward Curved Centrifugal Fan is a highly efficient and versa...

Centrifugal fans are devices designed to move air or gas efficiently by converting rotational energy from a motor into increased air pressure. They are widely used in industrial systems, HVAC applications, and other settings that require controlled airflow.

HVAC centrifugal fans provide consistent ventilation for heating, cooling, and air conditioning systems, ensuring energy-efficient air distribution. Multi-stage centrifugal fans feature multiple impellers in series, enabling higher pressure and enhanced airflow for more demanding applications, such as complex duct networks or large-scale industrial processes.

These fans are engineered for reliable performance, precise airflow control, and adaptability to various operational requirements.

After years of unremitting efforts, Qinlang's R&D team has achieved a number of technological achievements in the field of axial flow fan manufacturing, ensuring the integrity of the company's technical processes and the diversity of its products, and forming a deep technical reserve.

As a Multi Stage Centrifugal Fan Factory and HVAC Centrifugal Fan, our products are widely used in cooling and ventilation of various refrigeration, air conditioning, instruments, or for ventilation or purification of buildings, kitchens, industrial and mining enterprises, etc.

The company has won public praise for its leading technology and efficient management, and ranks among the best in the fan industry. Provide customers with high-quality products and good services. Based on the business philosophy of "people-oriented and forge ahead", the company relies on strong information resources and rich industry experience to minimize the procurement costs for customers and create the greatest benefits for customers.

Learn about our industry exhibition information and recent events in our company.

-

Key Features to Look For When you are looking for a duct silent fan, there are several aspects that ...

19 -

What Is a Duct Silent Fan A duct silent fan is a type of ventilation device designed to move air thr...

15 -

Factors to Consider When Selecting a Multi Stage Centrifugal Fan Deciding on a multi stage centrifug...

12 -

What Is a Multi Stage Centrifugal Fan? Multi stage centrifugal fan is a mechanical air moving device...

08

Comprehensive Guide to Centrifugal Fans in Industrial and HVAC Applications

Centrifugal fans are the "high-pressure airflow engines" of ventilation systems. Their core function is to convert the motor's rotational energy into higher air pressure, thereby efficiently transporting air. They are an indispensable ventilation core in industrial and commercial settings.

A key difference between centrifugal fans and axial fans lies in the direction of airflow: while axial fans deliver air along the axis of rotation, centrifugal fans exhaust air at a 90-degree angle to the air inlet. This design enables them to generate higher pressure and achieve more precise and controllable airflow.

In practical applications, they cover a wide range of functions:

- Industrial Applications: In factory settings, centrifugal fans act as the backbone of air management, driving essential processes like dust extraction, fume evacuation, and material transport. By efficiently removing airborne particles and controlling airflow, they help maintain a cleaner, safer production environment and ensure smooth operation of machinery.

- HVAC Systems: Within industrial and commercial facilities, centrifugal fans power the ventilation network, distributing heated or cooled air throughout the space. They optimize air circulation, reduce energy consumption, and support consistent indoor air quality, creating a comfortable and safe environment for workers while sustaining operational efficiency.

For engineers, designers, and maintenance professionals, understanding the types, operating principles, and application scenarios of centrifugal fans is a key prerequisite for optimizing ventilation system design and ensuring stable equipment operation.

Working Principle

- A centrifugal fan operates by accelerating air radially outward through a rotating impeller. As air enters the fan through the center (inlet), the spinning impeller imparts kinetic energy, pushing the air toward the fan casing. The fan housing then converts this kinetic energy into pressure, directing the airflow to the outlet duct. This radial movement allows centrifugal fans to generate higher pressures compared to axial fans, making them suitable for systems with long duct runs or high resistance.

Key Components

- Impeller: The core rotating element, available in various blade designs (backward-curved, forward-curved, radial). The impeller type affects efficiency, pressure, and noise levels.

- Housing / Casing: Guides airflow from the impeller to the outlet, often designed as a scroll or volute shape to optimize pressure conversion.

- Motor: Powers the impeller. Motors can be direct-driven or belt-driven, each with specific advantages in maintenance and performance.

- Inlet and Outlet: The fan's intake and discharge points. Proper design minimizes turbulence, reduces energy loss, and controls noise.

Types of Centrifugal Fans

Centrifugal fans come in multiple designs to suit different operational requirements:

- Single-stage fans: Feature one impeller, suitable for moderate pressure and airflow needs.

- Multi-stage fans: Include two or more impellers in series, allowing higher pressures for demanding industrial applications.

- Backward-curved and forward-curved fans: Blade design influences efficiency and performance; backward-curved fans are more energy-efficient, while forward-curved fans are compact and quiet.

- Radial fans: Simple and robust, ideal for handling particulates or high-temperature air.

HVAC Centrifugal Fans

HVAC centrifugal fans are specialized fans designed to provide reliable air circulation within heating, ventilation, and air conditioning systems. They are optimized for efficiency, noise reduction, and airflow consistency.

Role in HVAC Systems

- HVAC centrifugal fans ensure uniform air distribution, maintain indoor air quality, and support temperature control. They are commonly used in:

- Air handling units (AHUs)

- Ducted ventilation systems

- Commercial and residential HVAC installations

Design Considerations

- Energy efficiency: Properly sized fans reduce energy consumption while maintaining desired airflow and pressure.

- Compact design: Forward-curved fans are popular in HVAC applications for their compact size and quiet operation.

- System integration: Duct design, filters, and dampers affect fan performance; engineers must account for system resistance and pressure losses.

Common Challenges

- Dust accumulation on blades can reduce efficiency and increase noise.

- Imbalance or misalignment can lead to vibration and premature wear.

- Over-sizing fans can waste energy, while under-sizing can compromise ventilation performance.

Multi-Stage Centrifugal Fans

Multi-stage centrifugal fans consist of two or more impellers arranged in series within a single housing. Each stage increases the pressure of the air incrementally, allowing these fans to handle applications that require higher pressures than single-stage fans can provide.

Design and Structure

- Multiple impellers: Each impeller adds energy to the airflow, boosting static pressure.

- Intermediate casings: Separate housings or guide vanes between stages help stabilize airflow and improve efficiency.

- Materials: High-strength metals or corrosion-resistant alloys are often used due to the increased mechanical and thermal stress in multi-stage operation.

Advantages

- Higher pressure capability for complex or long duct systems

- Consistent airflow under varying system resistances

- Flexibility in adjusting performance by adding or removing stages

Typical Applications

- Industrial processes requiring high-pressure ventilation

- Large HVAC systems in commercial buildings

- Dust extraction and fume removal in chemical or manufacturing plants

- Cooling and air circulation in power plants

Applications Across Industries

Centrifugal fans are versatile and widely used across many sectors:

- Industrial Manufacturing: Dust collection, material handling, and process ventilation.

- Chemical and Pharmaceutical Plants: Corrosive or high-temperature air handling, fume extraction, and controlled environment ventilation.

- Food Processing: Maintaining air quality, controlling humidity, and providing clean airflow.

- Power Plants and Energy Sectors: Cooling systems, combustion air supply, and exhaust gas handling.

- Commercial HVAC Systems: Air circulation, temperature control, and indoor air quality maintenance in offices, shopping centers, and residential complexes.

Each application requires careful consideration of airflow, pressure, temperature, and environmental conditions to select the appropriate fan type and design.

Energy Efficiency and Modern Innovations

Centrifugal fan technology continues to evolve with a focus on energy savings and sustainability:

- Variable Frequency Drives (VFDs): Allow precise speed control, reducing energy consumption and improving system flexibility.

- Noise Reduction Technologies: Acoustic enclosures, backward-curved blades, and optimized casings minimize sound levels.

- High-Efficiency Impeller Designs: Advanced aerodynamics improve airflow and reduce power consumption.

- Sustainable Materials and Coatings: Corrosion-resistant and lightweight materials extend fan life while reducing energy use.

Modern innovations help reduce operational costs while maintaining high performance in industrial and HVAC applications.

Centrifugal fans are critical pieces of equipment in factory operations, ensuring proper ventilation, temperature control, and safe working conditions. Whether deployed as standard centrifugal fans, HVAC-specific units, or multi-stage fans, a thorough understanding of their design, performance, and maintenance requirements is essential for plant engineers and operations managers.

Selecting the right fan, installing it correctly, and maintaining it consistently directly impact production efficiency, energy consumption, and equipment longevity. Well-maintained centrifugal fans provide stable airflow for process control, prevent overheating of machinery, and help maintain a safe and comfortable environment for workers.

As manufacturing technologies advance, modern centrifugal fans offer improved energy efficiency, reduced noise, and greater adaptability to changing production demands. For factories, these fans are not just ventilation components—they are vital for sustaining continuous operations, protecting equipment, and supporting a safe, efficient, and productive workplace.

English

English русский

русский عربى

عربى Español

Español