Key Features

Hydraulic Control System

One of the protrude aspects of the Hydraulic Reverse Backward Curved Centrifugal Fan is its integrated hydraulic system. This system enhances control over the fan’s speed and tilt adjustments, enabling users to optimize airflow based on operational demands. The hydraulic mechanism allows for smoother performance while greatly reduced mechanical stress, dominant to increased efficiency and lower maintenance requirements.

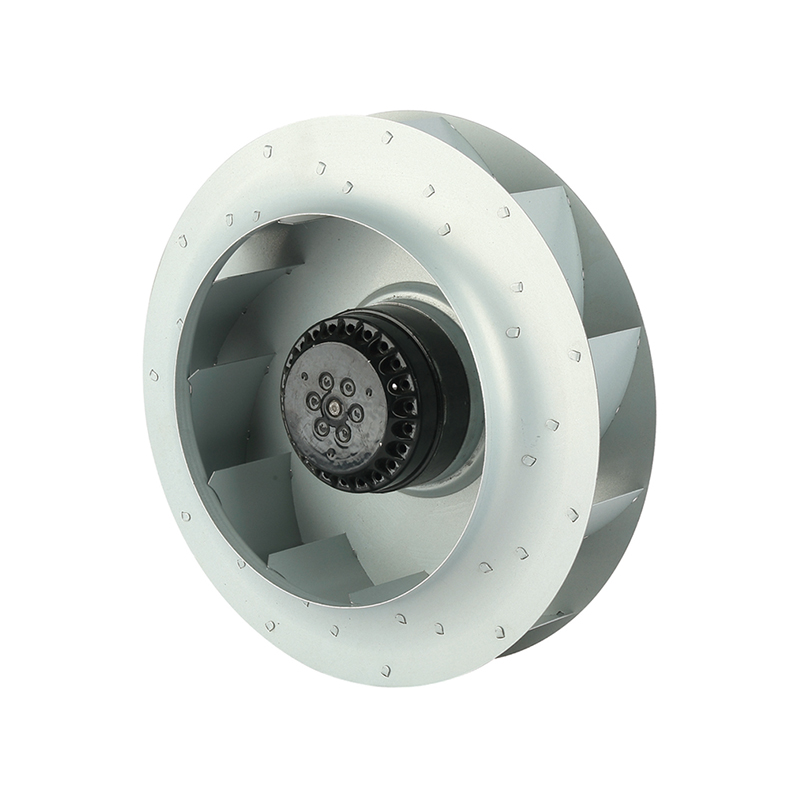

Backward Tilting Blade Design

The Hydraulic Reverse Backward Curved Centrifugal Fan features a Backward tilting blade design that significantly improves airflow management. This design reduces energy loss, enhances pressure stability, and ensures a more uniform distribution of air. The Backward tilting blades also contribute to noise reduction, making this centrifugal fan a priority choice for environments where maintaining lower noise levels is essential.

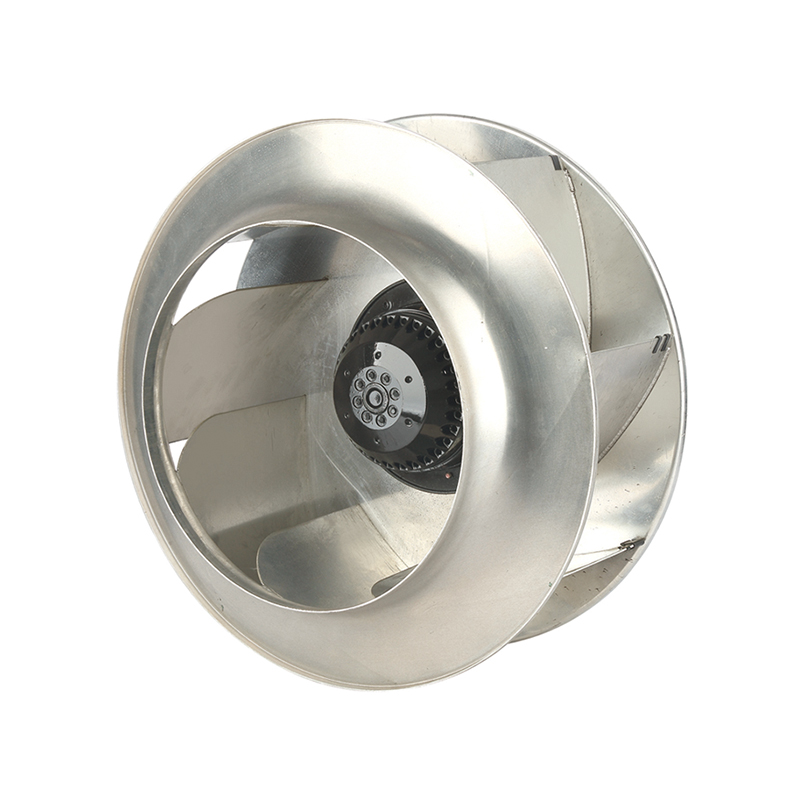

Robust Construction for Industrial Use

Durability is a critical factor in industrial applications, and the Hydraulic Reverse Backward Curved Centrifugal Fan is built to withstand demanding conditions. Manufactured using high-quality materials such as corrosion-resistant alloys and reinforced steel, this centrifugal fan ensures prolonged service life even in environments with high temperatures, humidity, or airborne contaminants.

Reverse Functionality for Enhanced Efficiency

A key advantage of the Hydraulic Reverse Backward Curved Centrifugal Fan is its reverse operation capability. This feature allows for better airflow regulation and facilitates self-cleaning by expelling dust and debris from the system. The reverse function enhances overall efficiency by reducing downtime caused by clogging, making it particularly valuable for heavy-duty applications.

Energy Efficiency and Cost-Effective Performance

Designed to optimize energy consumption, the Hydraulic Reverse Backward Curved Centrifugal Fan offers a balance between performance and power efficiency. The aerodynamic blade structure and hydraulic control system work together to reduce energy wastage while maintaining high airflow output. As a result, industries benefit from lower operational costs without compromising on performance.

Applications

Due to its robust design and advanced functionality, the Hydraulic Reverse Backward Curved Centrifugal Fan is widely used in various industrial sectors, including:

- Manufacturing Plants: Supports ventilation systems in production facilities, ensuring a steady supply of fresh air while expelling heat and fumes.

- Power Plants: Maintains stable airflow for combustion processes and cooling systems.

- Mining and Metal Processing: Facilitates air circulation in tunnels and industrial environments with high particulate matter.

- Chemical and Petrochemical Industries: Enhances workplace safety by controlling air quality and greatly reduced hazardous gas accumulation.

- HVac Systems: Provides efficient airflow management in large-scale ventilation setups.

The Hydraulic Reverse Backward Curved Centrifugal Fan is an innovative solution designed to meet the rigorous demands of industrial applications. With its hydraulic control system, Backward tilting blade design, durable construction, reverse functionality, and energy-efficient performance, this centrifugal fan delivers special airflow management with reduced maintenance needs. Industries looking for a reliable and cost-effective ventilation system can greatly benefit from the advanced features of the Hydraulic Reverse Backward Curved Centrifugal Fan, ensuring long-term operational efficiency and enhanced workplace conditions.

English

English русский

русский عربى

عربى Español

Español