Key Features of the Backward Curved Centrifugal Fan

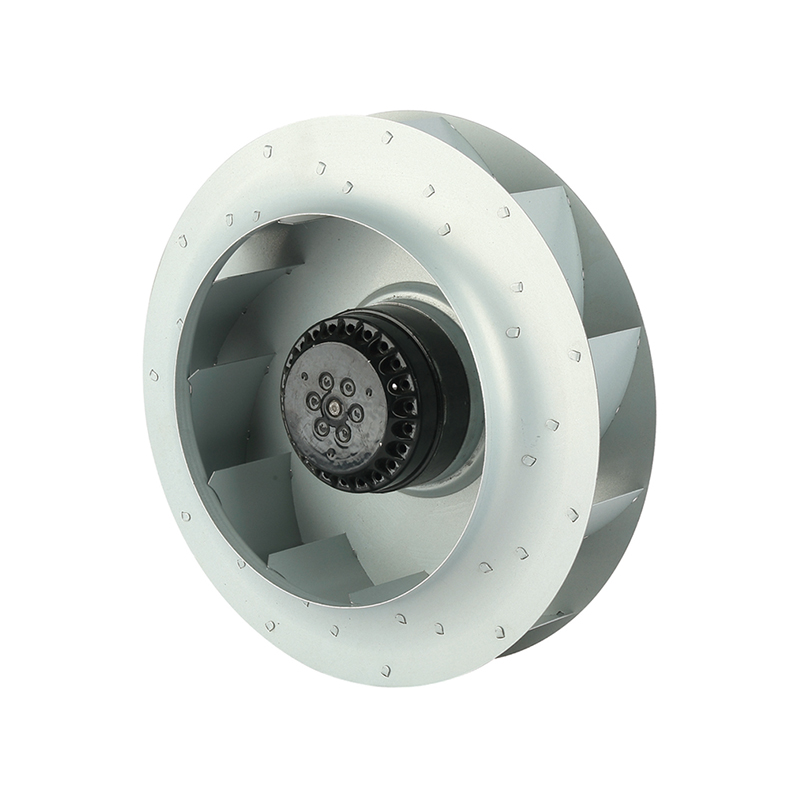

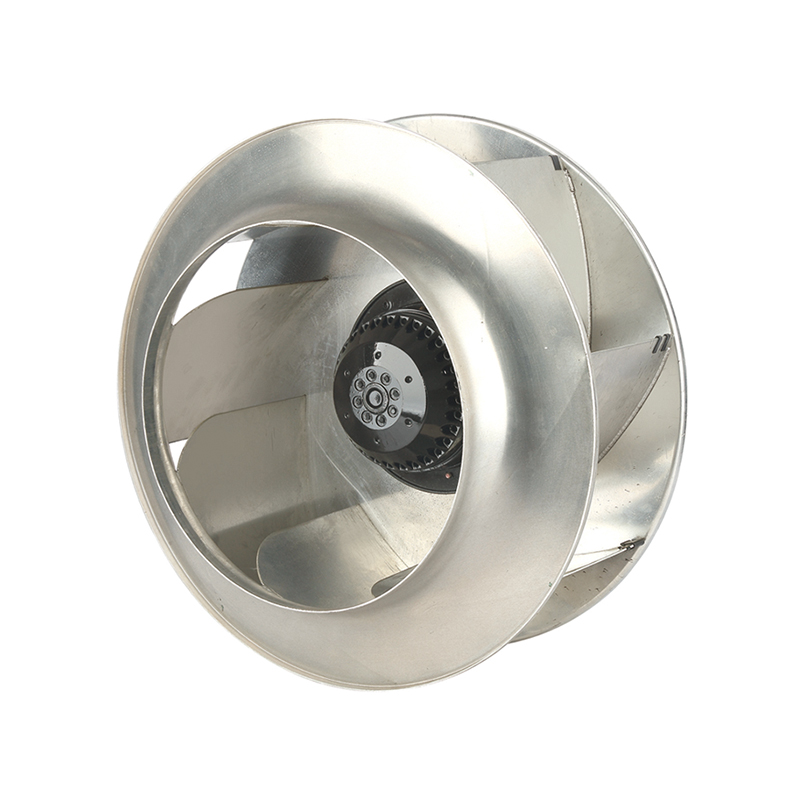

One of the protrude features of the Backward Curved Centrifugal Fan With Plastic Impeller is its Backward-tilted impeller design. This design helps reduce energy consumption by ensuring that the fan operates at peak efficiency, even under varying load conditions. The plastic impeller provides a lightweight yet strong construction, ensuring that the fan remains durable and long-lasting in demanding environments.

The fan’s Backward-tilting design also reduces the overall noise produced during operation. This makes it ideal for applications where greatly reduced noise is essential, such as in offices, libraries, and other noise-sensitive areas. The plastic impeller further contributes to reducing vibrations, dominant to quieter operation and a more stable airflow.

Durability and Longevity

The Backward Curved Centrifugal Fan With Plastic Impeller is built to last. The plastic material used for the impeller is resistant to corrosion, which is particularly beneficial in environments exposed to moisture or chemicals. Unlike metal impellers, the plastic impeller will not rust or deteriorate over time, ensuring that the fan continues to function bestly for years. This also makes the fan a cost-effective option in the long term, as it reduces the need for frequent maintenance or replacement.

Energy Efficiency

The Backward Curved Centrifugal Fan With Plastic Impeller is designed with energy efficiency in mind. The Backward-tilting impeller greatly reduced the energy required to move air, reducing the fan’s overall power consumption. This efficiency makes the fan an environmentally friendly option, helping to lower electricity bills and reduce carbon footprints.

Versatile Applications

Thanks to its versatile design, the Backward Curved Centrifugal Fan With Plastic Impeller can be used in a wide range of applications. Whether for cooling, ventilation, air filtration, or material handling, this fan meets the demands of diverse sectors, including HVac systems, industrial plants, and home ventilation setups.

Its ability to maintain consistent airflow and deliver high-pressure performance makes it suitable for systems with moderate to high resistance. The fan can effectively handle various airflow needs, making it ideal for applications such as ventilation in factories, exhaust systems in kitchens, or air supply in server rooms.

Ease of Installation and Maintenance

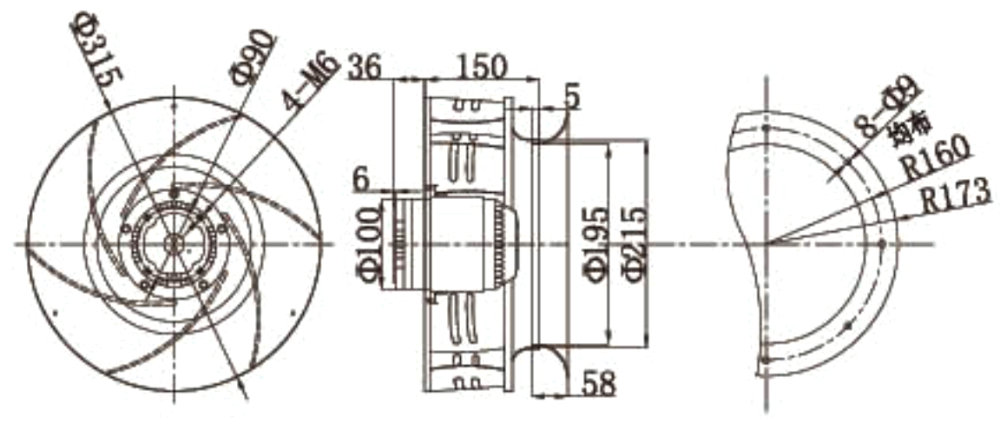

Another advantage of the Backward Curved Centrifugal Fan With Plastic Impeller is its ease of installation. The fan’s lightweight design, combined with a user-friendly mounting system, makes it simple to integrate into existing systems or new setups. Its compact size and efficient design ensure that it fits into tight spaces without compromising performance.

Maintenance of this fan is straightforward due to the durable plastic impeller and small moving parts. The fan is designed to be low-maintenance, reducing downtime and operational disruptions. Regular checks and cleaning are typically all that is needed to ensure best performance.

The Backward Curved Centrifugal Fan With Plastic Impeller is a reliable and efficient choice for a wide range of ventilation and air movement needs. Its advanced design, durable construction, and energy efficiency make it an good option for those looking to enhance airflow while reducing maintenance and operational costs.

English

English русский

русский عربى

عربى Español

Español